Yeast extract is a natural flavoring agent coming from fresh yeast. Yeast is a unicellular microorganism belonging to the fungus family, occurring in nature for millions of years.

It is a natural ingredient used to produce bread, wine or beer for centuries. First commercialized in the 1950’s, yeast extract is today enriching the taste of many food products, from soups to snacks. Like herbs and spices, it is used by food and flavor companies as well as restaurants as an aromatic ingredient to design more flavorful food and beverage applications.

In this article, we will discover what is yeast extract, and how it reshapes ordinary dishes into delicious meals. We also explain the natural process of extraction of the yeast cell content to obtain this food ingredient. And finally, we will see how this single food ingredient packed with proteins, vitamins, and umami taste is able to create so many flavors. Say goodbye to artificial additives and hello to a healthier way of eating!

Note: at Biospringer, we are specialized in yeast extracts for food products. However, yeast extract can also be used in other fields, such as animal feed, biotechnology, probiotics, cosmetics, and the medical industry. Today, we will only focus on yeast extract as a food ingredient.

If you are an R&D professional seeking for technical information on this food product, you can download Biospringer white paper on yeast extract.

If you are an R&D professional seeking for technical information on this food product, you can download Biospringer white paper on yeast extract.

What is yeast extract?

Yeast extract is coming from fresh yeast. To make it simple, it is the inner content of yeast cells, without the cell walls. No synthetic or chemical ingredients are added during its production. It develops its unique attributes and organoleptic qualities throughout the manufacturing process. Enzymes cut yeast proteins into short peptides and amino acids to release tasty components.

The main benefit of yeast extract is its ability to intensify perception of existing flavors and complexify and enrich the taste of food products. This ingredient is well-known worldwide and is frequently used by food manufacturers to create healthier recipes. Indeed, it allows us to avoid harmful food additives and ingredients such as sodium, MSG, HVP, and others that may negatively impact our health.

Yeast extract composition

Yeast extract composition is different from the composition of yeast. About 60% of its composition is a blend of proteins and amino acids, bringing specific notes including umami.

Yeast extract is one of those strategic ingredients that can replace many unhealthy ingredients in a recipe. The food industry actively seeks such ingredients to maintain or achieve clean labeling on their food products.

Is yeast extract MSG?

Yeast extract is not MSG. MSG stands for monosodium glutamate. MSG is a highly concentrated and processed form of glutamic acid. Glutamic acid is naturally present in various products, including tomatoes and mushrooms.

In a word, MSG is composed entirely of sodium glutamate. It is widely used in the food industry to enhance taste, but it is a synthetic ingredient.

In contrast, yeast extract naturally contains glutamate at a low percentage, approximately 5%, but also contains hundreds of other components such as proteins, peptides, amino acids, etc. Moreover, yeast extract is a natural origin ingredient. If you find articles conflating yeast extract and MSG, you can consider this connection to be false.

Is yeast extract natural?

Yeast extract has a natural origin, as it is derived from the process of fermentation. This makes it an invaluable ingredient for both food manufacturers and consumers, particularly due to its minimal processing. Here is the life cycle of Biospringer sustainable yeast-based ingredients:

Is yeast extract gluten free?

Yeast extracts are derived from baker’s yeast, which do not contain gluten as no gluten derivative is used during the process. Therefore, Biospringer’s products are gluten free, although few know the specifications of our products. However, gluten declaration or gluten-free status for yeast extracts depends on local regulations.

How is yeast extract made?

The production of yeast extract all starts from fresh yeast composed of a cell wall, cytoplasm (rich in nutrients such as proteins, free amino acids, vitamins, minerals) and nucleus.

Yeast extract production consists in three main steps.

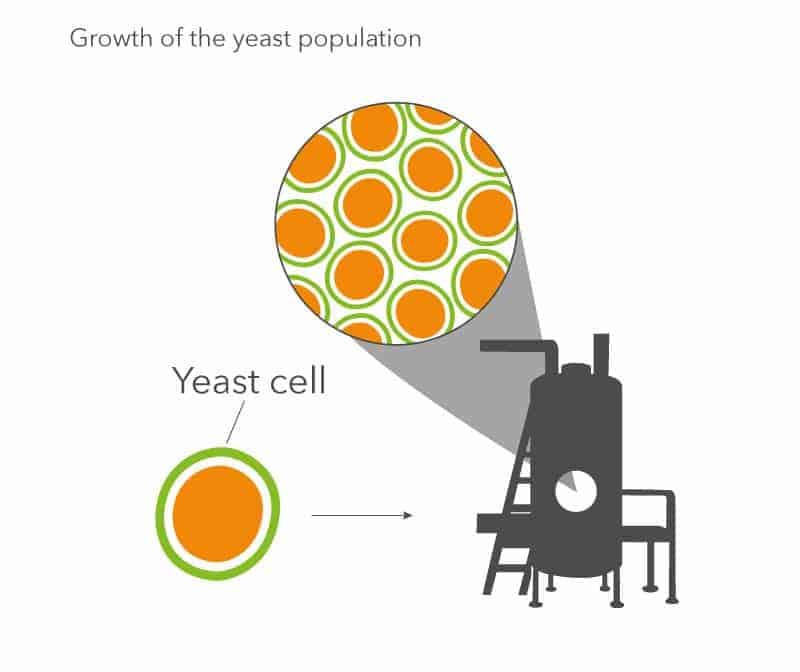

Fermentation of the yeast

Step 1

First, the yeast strain is selected to meet the customer’s final use. This strain will then grow, nourished by a sugar source. To optimize the growth rate of the yeast, temperature and oxygen levels are closely monitored. The result of the fermentation is called “Yeast cream”, ready to undergo the next step: the Breakage.

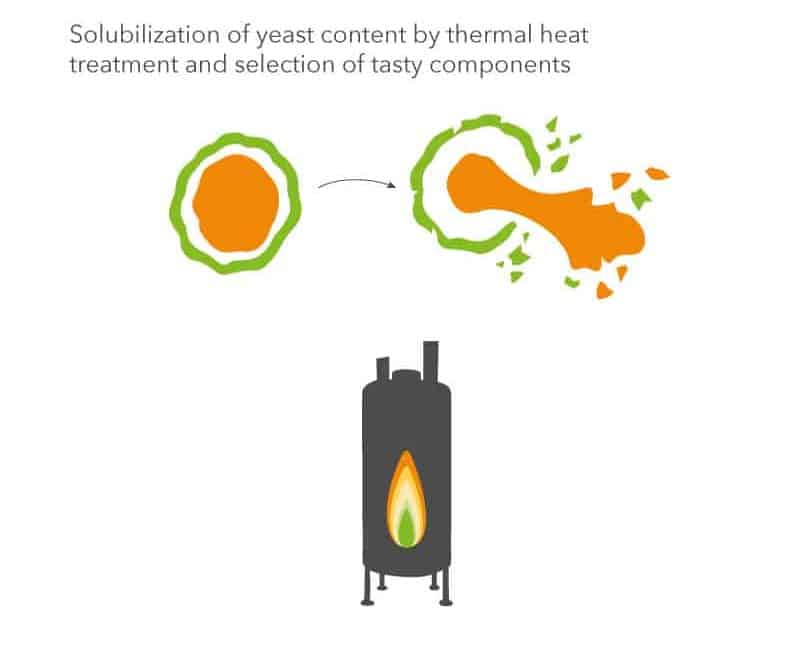

Breakage of the yeast

Step 2

Then, the second step is called the breakage, or disruption. This step induces a solubilization of the cell content. We use a scientific term to describe this step: autolysis process, to produce ``autolyzed yeast extract``. It allows the selection of tasty components.

The separation

Step 3

Finally, the last step is called the separation. Centrifugation allows the separation of cell walls from tasty components and nutrients obtained during the breakage. This centrifugation ends with a flavorful solution where organoleptic properties and qualities of the products are all preserved.

What does yeast extract taste like?

As a consumer, if you are interested in trying yeast extract, you can find it in food spreads such as Marmite® spread or Vegemite food spread, which are both made from brewer’s yeast.

Yeast extract can be found in various forms including liquid, paste, or powder, all of which are water-soluble. Food producers use yeast extract as a natural flavoring agent to develop various taste profiles.

Vegetal

aromatic

Meaty,

roasted

Salted

Toasted

cooked

Brothy notes

(chicken, beef, cheese)

Buttery

notes

What is

Umami ?

The most common taste associated with yeast extract is umami, which is one of the five primary tastes. Umami means “delicious” in Japanese. It describes a savory taste often found in broths or cooked meats. Our ingredients are naturally rich in umami. They usually work together with other ingredients in a recipe to improve or enhance the overall flavor profile.

What is yeast extract used for?

Yeast extract is not only used to improve taste, but also for its rich properties. In fact, it can naturally make a food formulation healthier (less salty, sweety or fatty), improve the nutritional profile of recipes or mask undesirable notes.

Here is a short summary to showcase yeast extract’s benefits in foods and beverages:

| Yeast type* | Main benefit | Properties |

|---|---|---|

| Yeast extract | Taste improvement | Natural, Vegan, Kosher-certified, Halal certified, Non-GMO certified, Gluten free |

| Yeast extract | Salt & sodium reduction | |

| Yeast extract | Sugar reduction | |

| Yeast extract | Fat reduction | |

| Yeast extract | Bring specific notes | |

| Yeast extract | Undesirable notes masking | |

| Yeast protein | Animal-free yeast protein | Natural, Vegan, Kosher-certified, Halal certified, Non-GMO certified |

*The label at the back of your food product may vary depending on local regulations.

How to use yeast extract?

This versatile ingredient is incorporated into many everyday consumer products and is very easy to use.

Yeast extract can be added to a variety of dishes, such as:

Depending on the food application and the objective of the food producer, the dosage will vary.

Who invented

yeast extract?

Yeast extract was invented by the German scientist Justus von Liebig during the 19th century. He was the first person to recognize the potential of yeast extract as a substitute for meat flavoring in dishes.

Yeast extract as an aromatic base to improve the flavors grew, until its introduction to the market in the 1950s. Biospringer is officially the first company to commercialize it in France, in 1959, after the World War II. Indeed, there was a strong consumer interest for nutritional food. It was initially used in bouillon and later became a common ingredient for many recipes.

What does Biospringer sell?

Biospringer is the world leading yeast extract manufacturer. Since more than 150 years, our R&D Center is developing the infinite potential of fermentation-based ingredients to develop tastier and healthier formulation. Thanks to our expertise and market knowledge, we have developed a wide range of products to meet our customers’expectations.

| Product Range | Product Type* | Main Characteristics | Main Benefits | Main Applications |

|---|---|---|---|---|

|

Springer® Reveal |

Dried Yeast Yeast extract |

Flavor base and Flavor carrier |

Taste Improvement | Processed Meat and Seafood Meat and Seafood Analogues Ready Meals Sauce & Dressing Snack and Seasoning Soup and Broth Sweet Products |

|

Springer® Umami |

Dried Yeast Yeast extract |

Umami | Taste Improvement Fat Reduction Salt Reduction Sugar Reduction |

Dairy Dairy Analogues Processed Meat and Seafood Meat and Seafood Analogues Ready Meals Sauce & Dressing Snack and Seasoning Soup and Broth |

|

Springer® Cocoon |

Yeast extract | Kokumi | Taste Improvement Fat Reduction |

Dairy Dairy Analogues Processed Meat and Seafood Meat and Seafood Analogues Ready Meals Sauce & Dressing Snack and Seasoning Soup and Broth Sweet Products |

|

Springer® Signature |

Dried Yeast Natural Flavor Flavor |

Specific flavor notes | Taste Improvement | Dairy Dairy Analogues Processed Meat and Seafood Meat and Seafood Analogues Ready Meals Sauce & Dressing Snack and Seasoning Soup and Broth Sweet Products Partial cocoa powder replacement |

|

Springer® Mask |

Dried Yeast Natural Flavor Flavor |

Mask off-notes | Off-note Masking | Beverages Dairy Dairy Analogues Processed Meat and Seafood Meat and Seafood Analogues Ready Meals Sauce & Dressing Snack and Seasoning Soup and Broth Sweet Products |

|

Springer® Precursor |

Yeast extract | Reacting yeast extracts for Maillard reaction |

Flavor Improvement | Flavors |

|

Springer® Proteissimo |

Yeast protein | Vegan Protein with a neutral taste |

Protein Source | Beverages (protein shakes) Dairy Analogues Processed Meat and Seafood Meat and Seafood Analogues Ready Meals Sweet Products |

*Label may vary depending on local regulations.

Other Frequently Asked Questions

Is yeast extract the same as yeast?

Is yeast extract the same as nutritional yeast?

Yeast extract differs from nutritional yeast in that it does not contain intact yeast cell walls, unlike nutritional yeast. However, Biospringer Springer® Reveal Range includes dried yeast, which is equivalent to nutritional yeast.

Is yeast extract same as Marmite®?

While yeast extract is the primary ingredient in Marmite® and Vegemite, these spreads contain additional ingredients such as salt, vegetable juice concentrate and vitamins.

What foods contain yeast extract?

Yeast extract is suitable for any kind of food: soups & broths, sauces & dressings, snacks seasonings, ready meals, meat, dairy, seafood and analogues, processed meat, sweet products and beverages. You may find it in a lot of different food products from your supermarket.

Yeast extract is a highly valuable (but also little-known) ingredient that raises many questions from both consumers and food manufacturers. Its numerous benefits make it a must-have for most food manufacturers worldwide. Indeed, between consumers being more careful about what they eat and the World Health Organization’s new guidelines for healthier foods1, food formulators are reassessing their ingredient lists. Thus, yeast extract being a very clean alternative, the market is growing every year. That’s why at Biospringer, we are committed to having production plants all over the world. This way, we ensure that our customers have local production capacity. We hope we have addressed all your questions. If that’s not the case, we invite you to download our Biospringer white paper on yeast extract.

At Biospringer, we believe that working with our customers is the key to providing quality specialist food ingredients, wherever they are. With 10 manufacturing plants and 6 Culinary Centers around the world, Biospringer offers expert support that’s tailored to local markets and trends.

Do you need more information? Feel free to contact our teams!