The sweet biscuits/cookies’ market value is 17.3 Billion USD in Asia.¹

It demonstrates a growth of 3.4% between 2023 and 2024.² This consistent growth, combined with the high number of new product launches, reflects not only the dynamism of the sweet biscuits category in Asia but also the increasing pressure to stand out in a crowded market.

For R&D teams, this means that differentiation through taste, texture, nutritional profile, or clean label positioning is becoming more critical than ever to capture consumer attention and drive long-term success.

Meanwhile, food manufacturers are constantly challenged to control increasing costs due to global crises such as cocoa powder shortages. In this article, Biospringer’s experts explain the potential of yeast extracts to develop healthy, tasty and cost-optimized sweet biscuits.

Finding a balance between taste and indulgence in sweet biscuits

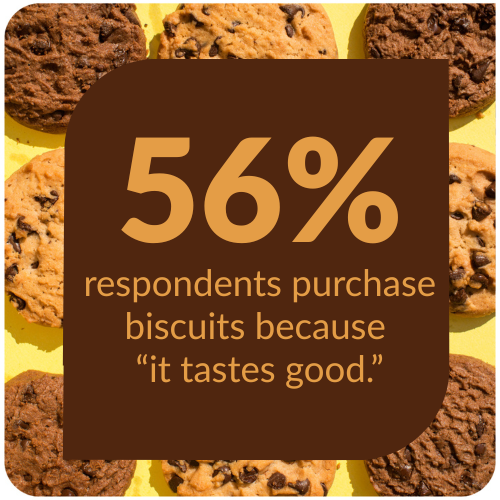

In Asia, taste remains the leading factor driving consumers’ choice in the sweet biscuit category.

In the first half of 2025, for instance, 56% of Asian respondents said they purchase sweet biscuits and cookies simply because “it tastes good.”³

While health, price, and convenience also play important roles, taste is the key to winning initial trials and securing repeat purchases.

To be competitive, manufacturers need to strike a careful balance between indulgent flavor and health-conscious innovation.

Across the region, demand is rising for products with less sugar, cleaner labels, and added nutritional value.

Brands that successfully deliver both pleasure and wellness will be best positioned to meet evolving consumer expectations and foster long-term loyalty.

The future of sweet biscuits lies in creating products that no longer force consumers to choose between great taste and better-for-you options.

Benefit

Taste and texture improvement using yeast extracts

1. How to improve taste and mouthfeel naturally?

Consumers always welcome better-tasting products, especially if they are enhanced versions of their favorite.

Yeast extracts are versatile and can be used to

- improve the taste and mouthfeel of products consumers love,

- act as a booster when used on top of original recipes.

Although yeast extracts are commonly associated with only savoury products, they can also perform well in sweet applications.

Demonstrating this versatile use of yeast extract, the innovation team at Biospringer has developed natural solutions that perfectly highlight the distinctive bitter, smooth vegetal, and subtly sweet notes that consumers love in matcha products.

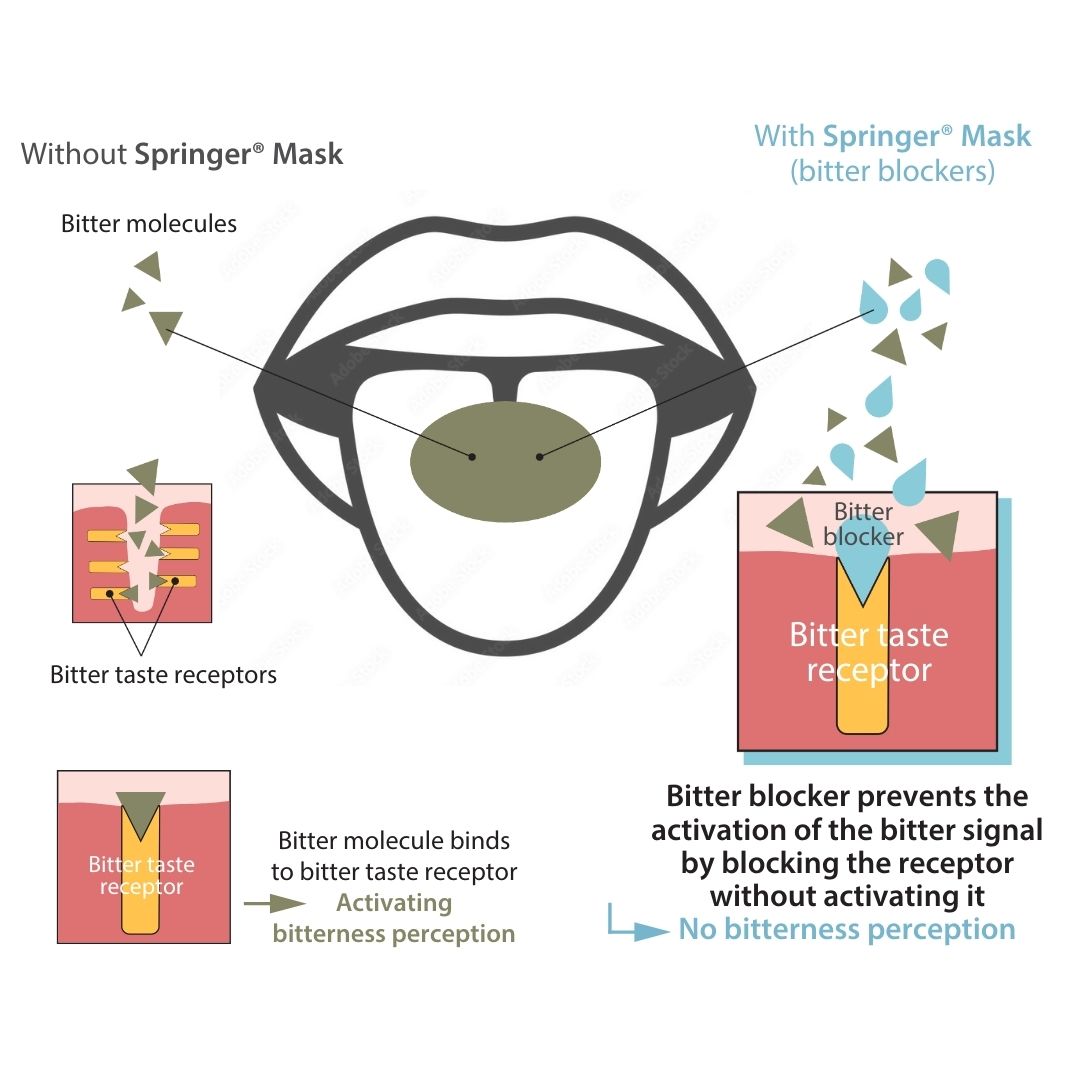

2. How to mask undesirable notes coming from healthy ingredients?

Masking off-notes is one of the key challenges manufacturers face when developing healthy yet indulgent products.

Ingredients like soy, oat powder, and multigrain can introduce unwanted flavors that may affect overall taste perception.

Our Biospringer’s experts are well aware of this challenge. That is the reason why they have developed a natural solution that can mask a wide variety of off-notes.

In high-protein cookies, added proteins can introduce unwanted off-notes, such as the beany flavor from soy protein that consumers may find unpleasant.

Effectively masking these off-notes while maintaining the nutritional benefits is crucial for satisfying health-conscious consumers who expect both functionality and enjoyable taste.

Benefit

Reduce raw materials to optimize costs using yeast extract

Besides the incorporation of healthy ingredients, food manufacturers are facing raw material shortages in recent years, which has caused price volatility and unstable supply.

Several crises of raw materials are ongoing worldwide, with some of them directly impacting the sweet biscuits category. Among them, we can think of the cocoa powder or the matcha powder crisis. To address these challenges, our experts developed dedicated solutions to improve taste while optimizing costs.

3. Reduce cocoa powder in your chocolate-related products using yeast extracts

The global cocoa powder crisis, driven by extreme weather conditions in West Africa and crop disease, has led to the highest cocoa prices in decades.

With supply tightening and costs soaring, food manufacturers are under intense pressure to rethink their recipes.

From baked goods to chocolate-flavored snacks and beverages, many are being forced to reduce cocoa content or explore alternative ingredients to maintain profitability without compromising taste or quality. This unprecedented situation is pushing R&D teams to innovate rapidly while managing consumer expectations.

Biospringer’s technical teams, called “Culinary Center”, have been fully mobilized to tackle this challenge and support food manufacturers facing cocoa powder shortages.

Drawing on their expertise in taste and natural ingredients, they’ve developed tailored solutions to help reduce cocoa content in recipes while preserving the rich, indulgent flavor consumers expect.

These innovations aim to ease cost pressures without compromising on quality or product appeal.

4. Develop recipes with reduced butter using yeast extract

Traditionally, butter is often used in recipes of sweet biscuits, for their ability to impart flavor, texture and structure.

However, butter is usually one of the ingredients with the highest cost, with price fluctuations caused by the dairy market volatility.

The use of alternative ingredients would be a good option, however, reducing butter would affect the taste and texture of the product.

This in turn impacts consumers’ purchase decisions, as taste is the key purchase driver.

To tackle this issue, Biospringer’s experts worked on a natural, fermentation-based solution, to create butter cookies with a 20% reduction in the use of butter, without compromising the taste and flavor consumers are after.

Biospringer: Your trusted partner for healthy, tasty, and cost-optimized sweet biscuits

With more than 150 years of experience in fermentation and 10 factories worldwide, Biospringer is the world’s leading yeast extract manufacturer.

Our Culinary Centers, composed of regional technical teams, are collaborating with your R&D teams worldwide to develop tailor-made solutions in sweet biscuits.

Contact our teams to share your technical challenges, and let’s collaborate on innovative solutions for a healthier and tastier future!

Access our full set of sweet biscuit recipes using yeast extract.

Other frequently asked questions

Is umami sweet?

No, umami is not sweet. Umami comes from naturally occurring compounds such as nucleotides, and it enhances the overall depth of flavor in food. It’s smooth and lingering, but not sugary or sweet. That said, sweetness and umami can complement each other in balanced recipes. For example, in sweet-savory sauces or snacks.

I want to develop gluten free sweet biscuits, is yeast extract gluten free?

Yeast extracts are made from baker’s yeast and do not involve any gluten-containing ingredients during production. As a result, Biospringer’s yeast extracts are gluten-free by composition. However, the declaration of gluten content or gluten-free status may vary depending on local regulatory requirements.

Sources:

¹Innova | Market sizing, 2024

²Innova | Market sizing, 2023 – 2024

³Innova | Category survey, 2025, including Indonesia, India, Japan, Malaysia, Philippines, South Korea, Thailand, Vietnam, New Zealand and Australia