Meat analogues: a growing industry

The days of meat substitutes being products only for vegans and vegetarians are long gone. Whether for health, environmental or financial reasons, consumers are turning towards meat analogues and similar foods.

In a recent study, 49% of respondents reported having tried meat analogue products (Consumer Research: Plant Alternatives to meat). Between 32% and 74% of consumers eat them at least monthly (Innova Insights – 2019). Some researchers predict that two of the main types of meat replacements – plant-based meat analogues and cultured meat – will be the main sources of proteins in global diets by 2040 (Les Echos, d’après A.T. Kearney, L’essor inexorable des alternatives à la viande, 2019).

Health and environmental benefits of meat analogues

With vegetarianism, veganism and flexitarianism on the rise, meat-free diets are becoming a positive consumer choice.

Meat analogues can be a gateway to a healthier lifestyle of reduced meat consumption. It allows consumers to substitute meat on their plate occasionally, rather than changing their eating habits completely.

Environmental concerns are also an issue. As a matter of fact, 18% of U.S. consumers report that their decision to buy meat and dairy alternatives is driven by sustainability issues. (Innova Market Insights consumer survey, 2018 – U.S.)

Many individuals are simultaneously concerned they’re not consuming enough protein and looking to supplement the nutrient in their diet. In fact, 59% of adults in the UK say high-protein content is a primary part of their purchasing choice for alternative proteins, while 32% say it’s a way to improve health. (Lightspeed/Mintel; Mintel GNPD)

Among global consumers, about 27% report trying to eat more protein, with more than one in three Millennials claiming to consume as much protein as possible. These younger, health-conscious consumers are aware of the potential negative impacts of meat consumption. However, they still crave a relatively high level of protein.

Creating meat analogues: challenges

Today, the opportunity for innovation in the meat analogue space is enormous. Manufacturers who are able to find great tasting, high nutritional quality ingredients are building the legacy brands and products of the future

Unsurprisingly, the most significant barrier to building a mainstream audience continues to be taste. 68% of consumers say taste and flavor are the most important factor they consider when choosing meat analogues (Mintel, 2018). In fact, a majority of consumers believe that plant-based alternatives should taste like meat. (Mintel, Plant-based proteins, May 2019)

Alternative high-protein sources, from the well-known (soy) to newcomers (algae) are often introducing off-flavors and colors that can be difficult to manage when creating innovative products. Thus, formulators can find it challenging to create delicious products to tempt this growing market.

So, how can food developers create meat analogues that respond to consumer expectations about texture, nutritional content and – most importantly – delicious taste? The secret lies in Biospringer’s area of expertise: yeast and yeast-derived ingredients.

Biospringer: Taking meat analogues to a new level

Yeast ingredients: the secret to delicious meat analogues

Yeast and yeast-derived products open up a whole new world of possibilities when it comes to developing alternative meat products.

Yeast-derived ingredients can help to mask the off-notes that can accompany traditional meat analogues, including bitterness, “beany,” or “earthy” notes, or “cardboard-like” tastes and textures.

They can also help to recreate savory notes traditionally associated with meat and poultry, including delicious umami tastes and satisfying mouthfeel (‘kokumi’).

Biospringer: 150 years of expertise

Ever since Biospringer’s founding in 1853, we’ve been passionate about yeast and yeast derived products. Initially a staple of the baking industry, yeast’s popularity as a food ingredient took off in the interwar period, with meat shortages leading to innovations with yeast as a source of protein.

Biospringer’s yeast extract has been used since the 1960s to give plant or meaty aromatic notes to many savory foodstuffs, from stocks and soups to sauces and ready meals.

Thanks to Biospringer’s unique range of yeast-derived ingredients, food formulators no longer have to choose between prioritizing reduced processing and few added ingredients, or prioritizing great taste.

With a network of Culinary Centers, R&D and Sensory Analysis experts around the world, Biospringer puts the very best of yeast-derived products at food formulators’ fingertips.

Meat analogues that taste like meat with Biospringer

Delicious Products That Delight Customers

Recreating an authentic taste in meat analogue products often requires additives like salt or sugar to mask off-notes. It detracts from the high value target consumers put on nutritional aspects like clean labels and lack of processing.

Biospringer’s expertise centers around finding and refining yeast ingredients that recreate a delicious taste

Biospringer’s 7 Key Ranges:

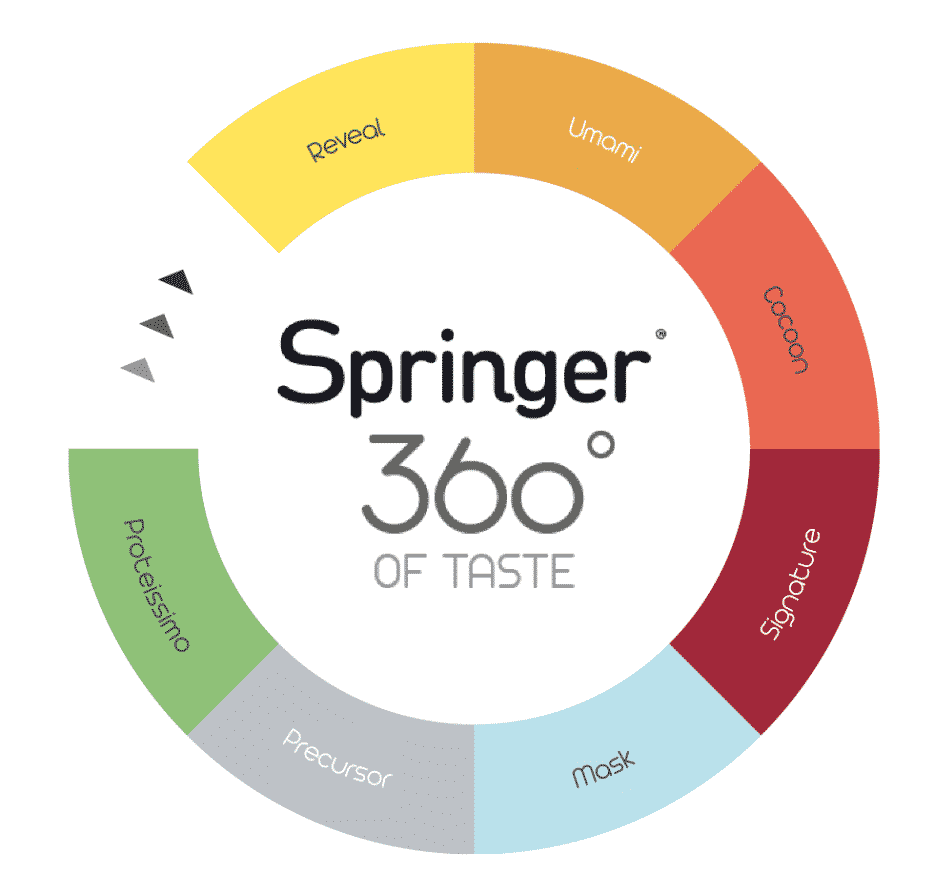

A 360° Wheel Of Taste For Food Developers

From red meat to poultry, burgers to steaks, Biospringer’s delicious yeast-derived ingredients guarantee delicious meat analogues with great taste, great texture and a real mouthfeel.

Composed of seven key ranges destined for food and beverage formulators, Biospringer’s 360° Wheel of Taste offers a variety of tastes and benefits. For example, Springer® Mask helps to mask unpleasant flavor notes, while Springer® Signature provides specific flavors, such as beef or chicken.

Take Your Food Further With Yeast Ingredients

In addition to masking undesirable off-notes, yeast extract also brings out the tastes profiles of other ingredients, particularly umami, and it illuminates brown flavor notes like grilled or roasted that help meat analogue products achieve those really meaty flavors.

Springer® Umami helps fit meaty flavors seamlessly into vegan and vegetarian diets, as well as those concerned about environmental sustainability, while Springer® Proteissimo acts as a great source of

yeast-based protein.

Innovation For Today And Tomorrow

Products with a purpose:

Biospringer’s commitment to innovation

Biospringer’s products are innovative, consumer-oriented, and can be used in all types of food applications: food and beverages, dairy alternatives and meat analogues, and sweet and savory recipes.

- Great taste, texture, aroma, and appearance

- No allergens or GMOs

- Relatively low processing

- Look, cook, and seem like meat

- Short and similar ingredient list

- High protein content

- Low environmental impact

Great taste, texture,

aroma, and appearance

The complexe and unique composition of yeast, close to the one of meat.

Combined with the expertise of Biospringer, yeast-based ingredients offer infinite possibilities in terms of taste > Intensifying meat profile (Springer® Reveal), bringing umami (Springer® Umami), masking ingredient off-notes (Springer® Mask)

Relatively

low processing

Simple process made of only 3 steps:

fermentation, breakage and separation

Look, cook, and

seem like meat

Springer® Signature offers range of specific meat profiles, great tool to develop meaty flavor profile in meat analogues.

High protein

content

Innovative source of protein, is a Springer Proteissimo yeast protein and contains 70% of protein contribuin.

Anticipating tomorrow’s trends

As a key player and innovator in the food ingredient sector, we are at the forefront of innovation when it comes to developing flavorful products from yeast and fermentation. The challenge: expertly blend protein and other clean ingredients to achieve “just like meat” flavors.

Let’s take a closer look at some leading trends in the future of meat substitutes:

Plant-based substitutes

Plant-based meat analogues are more popular than ever. Pea protein is poised to define the high end of plant-based foods, despite struggling with offnotes, particularly strong “earthy” or “beany” flavors, and often inherent color issues as well (McKinsey, Alternative Meats: the race for market share is on).

Crops of peas tend to have a more limited environmental impact than soybeans, as well as fewer allergens and the benefit of their non-GMO status. Other emerging sources of plant-based proteins include lentils, chickpeas and fava beans.

Insects

Most insect protein products on the market rely on milled cricket flour. Although isolating protein from crickets is still costly at scale, there is significant potential for this market to grow: insects are a great source of bio-available protein, can be grown quickly, and are more efficient at turning feed into consumable protein than other livestock.

Fungi

Yeast is derived from a micro-organism naturally present in our environment, and produced by fermentation – a natural process that makes yeast a great choice for creating meat analogues from the fungi family.

Protein captured from the common mold fungus is another excellent form of protein, representing about 40% protein by mass. A popular choice with health-conscious consumers, fungi protein offers numerous health benefits, including high quantities of fiber, few carbohydrates, and no cholesterol.

Get a closer look at meat analogue products and upcoming food trends