Biospringer’s mission

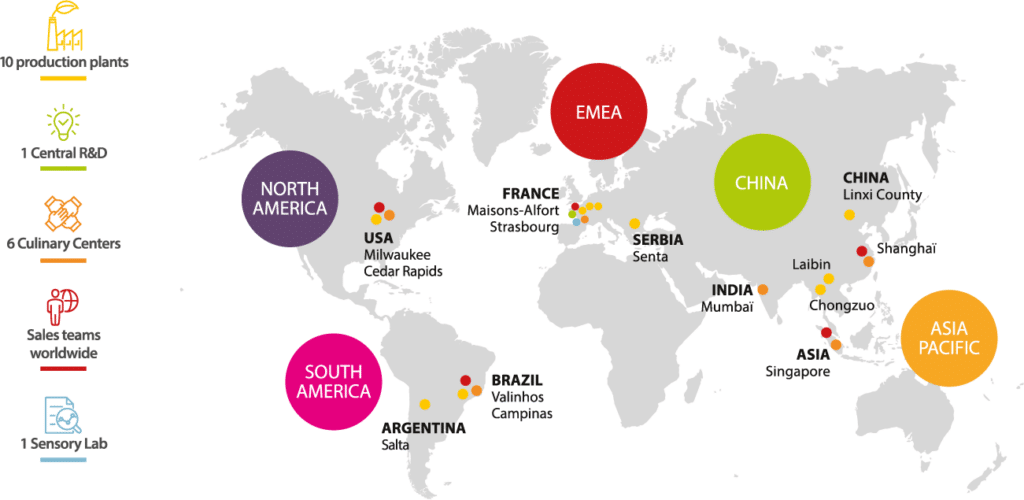

At Biospringer, we’re proud to be a specialist in creating food ingredients from yeast. Our mission is simple: we partner with our clients to create innovative and natural origin ingredients from yeast fermentation, helping to make food tastier and healthier while being reliable and respectful of the planet and people.

With our extensive product range, dedicated technical and scientific teams, and extensive R&D, we help our customers to develop flavorful recipes, solve specific development challenges, and create healthy and nutritionally balanced products. As a business unit of Lesaffre, Biospringer offers innovative solutions that are as relevant now as they were at our founding, back in 1872.

BIOSPRINGER is a trademark and it does not imply systematically that the product is organic according to EU Regulation 2018/ 848, the status of each product supplied should be checked on the technical documentation.